We are delighted to announce that the Q3edge Knowledge Academy’s new learning session includes a comprehensive Six Sigma Green Belt Certification program. This program is a unique opportunity for professionals to develop and acquire new skill sets, knowledge, and capabilities in the field of Six Sigma.

Q3edge’s approach to learning and acquisition of new skill sets follows a long-practiced methodology of Learn, Practice, Excel. Our Six Sigma Green Belt Certification program is designed in accordance with the best practices of human behavior science and learning patterns of the human mind.

Our state-of-the-art conceptualized and developed Six Sigma Green Belt Certification program equips professionals with the necessary tools and techniques to identify and eliminate defects in business processes. Upon completion of the program, participants will have a thorough understanding of the Six Sigma methodology and will be able to lead and execute process improvement projects.

Enroll now in our Six Sigma Green Belt Certification program and take the first step towards enhancing your professional growth and career advancement.

Each Program is divided into multiple learning sessions and each learning session comprises of learning into three phases:

1. Learn

This phase emphasis on the conceptual knowledge. The content is designed using pictures and text combination. The purpose of Learning session is to build conceptual knowledge about the subject to the participants. The right information is the key for any learning.

2. Practice

This phase is completely designed with the concept to learn by doing. Various exercises are planned in this phase to learn the concept through practical learning. There are various simulation exercises are planned as part of the course.

3. Excel

Excel is a phase where you collaborate with your peers to discuss and learn from others. Knowledge is enhanced when it is shared with others. As part of this phase, we discuss and share our knowledge with our fellow delegates and explore other problem areas which can be better supported through this newly acquired knowledge and skill.

Why Q3edge

Q3edge designed LEAN Six Sigma Program does not focus around “statistics”. Our six sigma green belt certification program ensures that every participant becomes a business analyst to identify, evaluate

and optimize business problems.

1. Our LEAN Six Sigma green belt certification program includes technical plus soft behavioral aspects too. We believe a right technical solution holds no good unless right mindset is available too. Hence, our program includes Critical Thinking and Process Innovation tools as part of LEAN Six Sigma. This makes us completely different and unique from the industry.

2. It is not just a class room session with concept learning, each participant gets a real business problem with relevant data. At the end of the session, every participant walks out with the implementation of end to end business problem with hands-on on experience of Lean Six Sigma methodology

Course Benefit

• Lead organization function team for improvement initiative

• Increase bottom line benefit for the organization

• Identify and deploy innovation in organization

• Professional and personal advancement for problem solving approach

Examination

Time: 4:00 PM – 5:00 PM

End of Six Sigma Green Belt Certification Program

Six Sigma Green Belt Certification is skilled team players and their aim is to improve process quality. They help to bridge the gap between the real-world application and Six Sigma theory. Six Sigma Green Belt candidates play a major role in improving the process, Project Management, and Data Inspection.

Transform your operations, achieve your goals

with our expert BPM consulting.

How the Business Process Reengineering works? | Methodology

Business Process Reengineering (BPR) is a sensational initiative for change. Its methodology is based on five core areas, which are laid as follows:

- Refocus: Align company values with the customer needs and demands.

- Redesign: Draft and design core processes to enable improvements using information technology (IT).

- Reorganize: Convert individual teams into cross-functional teams to hold up end-to-end responsibility of a process.

- Rethink: Think about the basic organizational needs and issues people facing with the current system.

- Improve: Keep in mind all the business processes across the organization and work to improve them.

Week 1

Session 1: An overview Session for Six Sigma

Learning Objective

Learn about the basics of Six Sigma, it’s evaluation, industry need. This is a foundation session that explains the

purpose of this skill, why this skill identified as an essential “need “ for the industry, how did organization get

benefited with the right use of this skill, list of challenges and best practices adopted by the organizations.

Course Content:

1. Team Welcome, Introduction and Expectation Setting

2. An Introduction to Six Sigma, history and best practices

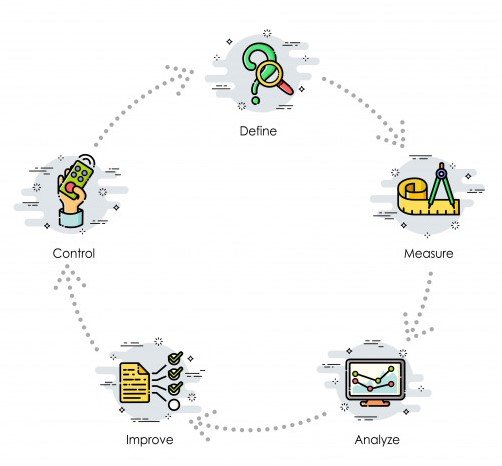

3. An understanding of Six Sigma Methodology: Define, Measure, Analyze, Improve, and Control

Session 2: Six Sigma : Define Phase

Learning Objective

Define is the first phase of Six Sigma. Not every problem holds the same value and priority for resolution. Define

phase helps to identify, select and prioritize the business problem. It helps to break down the big problem into

small resolvable problems. At the end of this session, you will learn which problem should be addressed, with

whom and how. Sometimes, an effective execution of define phase provides the sustainable solution to the

problem before getting into more detail.

Course Content:

1. Problem Selection, Evaluation using Project Tree and Critical to Quality

2. Set Scope, Team and Targets using Business Charter

3. Explore Business Process Maps to Find Quick Wins

Week 2

Session 3: Measure Phase

Learning Objective

“How big is the problem” is the question which is evaluated using this tools, techniques of this phase. In Measure

phase, we learn about how to measure the capability of a process. In addition, before measuring the capability of

any process, measure the quality of the measurement system. At the end of this session, you will be able to learn

two capabilities : Measure the Capability of the Measurement System, Measure the Process Capability

Course Content:

1. Data Collection : Sample and Population

2. Statistics Based on Data “Type”

3. Measurement System Analysis

4. Process Capability and Defect Per Million Opportunity (DPMO)

Session 4: Six Sigma : Analyze Phase

Learning Objective

Problems are the symptoms which are visible and experienced by the business users. In this phase, we learn to

find the potential root causes and validate potential root causes using Hypothesis Testing methods to confirm the

“real” root cause.

Course Content:

1. Learn about Hypothesis Tests

2. 7QC Basic Statistics Tools

Week 3

Session 5: Improve Phase

Learning Objective

In this phase, we learn about Innovating Techniques to identify the potential best solutions. Also, we learn about

how a solution should be planned to execute and validate using the Pilot Phase.

Course Content:

1. Process Innovation for Best Solution Identification and Selection

2. Pilot Project Approach

3. Pilot Solution Validation

4. Control Chart Monitoring and Analysis

Session 6: Six Sigma : Control Phase

Learning Objective

Change Management is the essential part of the right solution implementation. Even the best solutions fail in the

real world if the change is not managed effectively. In this phase, we will learn about the change management

approach with the right communication method to ensure that solution is accepted, implemented and sustained

in the real world.

Course Content:

1. Change Management Approach and Best Practices

2. Sustain through Control Charts, SOP and Poka Yoka

A “Yellow Belt” level of knowledge about Six Sigma is highly recommended. This can be acquired by successful completion of the Six Sigma Yellow Belt Certificate

Those having a strong business background and a firm understanding of basic business operations and principles will do better in this specialization.

- Lean Six Sigma Consultant.

- Lead Manufacturing Engineer.

- Process Development Engineer.

- Compliance Structural Engineer.

- Reliability Engineer.

- Operating System Specialist.

- Senior IT Project Manager.

- Warehouse Operations Manager

So, Six Sigma as an improvement methodology is worth the investment. But, if you thought that it was a Certification to deck up your resume, then it is being short-sighted.